Makerspace Safety Induction

GENERAL

General

We ask you to remember these four key principles when using the Makerspace and approaching any piece of equipment.

- Check the environment for potential hazards.

- Check the equipment for potential hazards.

- Check yourself for potential hazards.

- Check with staff if you are unsure.

Here are some specific safety requirements:

- Enclosed shoes must be worn at all times when in the Makerspace.

- Make sure to read the safety signage before using any equipment.

- Use appropriate PPE (personal protective equipment) whenever using any of the tools.

- Before using any equipment make sure to tie back loose hair, clothing or jewellery.

- Check the area for any potential hazards and make sure it is clean and clear.

- Do not use any equipment that is visibly damaged and immediately inform staff.

- Only use tools and equipment from the Makerspace.

- All personal repair projects must be approved by the on-site facilitator. Note: We are not equipped to handle mains electrical equipment.

- If you are unsure of anything, check with a member of staff.

3D PRINTERS

3D Printers

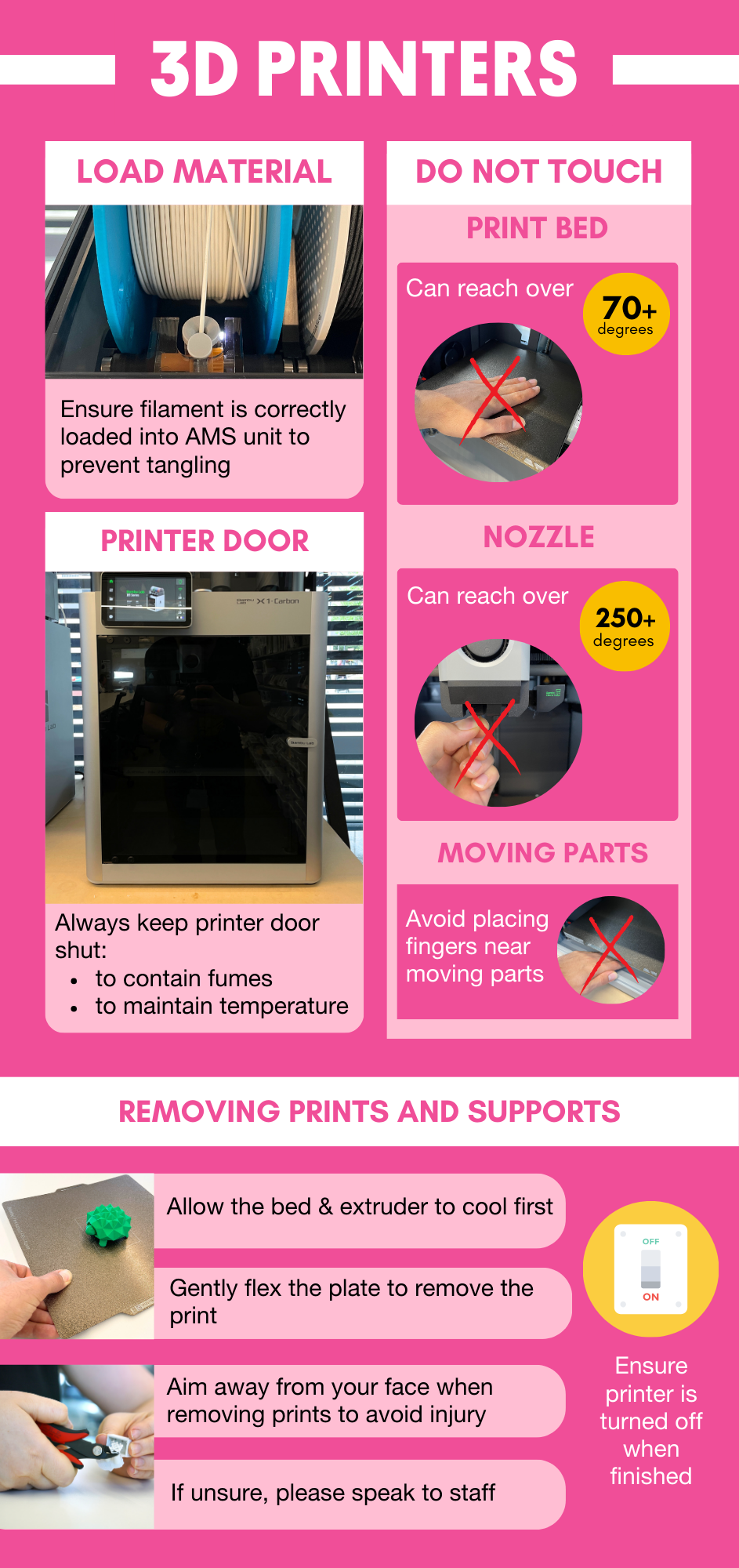

- After checking that the area is clear and the equipment is in good working order and free of obstructions, turn on the extraction fan next to the printer to remove any fumes.

- Do not touch the print bed as it can exceed 40 degrees.

- Do not touch the nozzle as it can exceed 200 degrees. If waste needs to be removed from the nozzle, please clean with a brass brush, pliers or tweezers.

- Ensure the door is closed on the printer at all times to prevent anything getting caught in the moving parts, to contain fumes and to maintain temperature. Leave a gap of approximately one hand width between the zips to allow air to flow into the enclosure..

- Do not put your fingers under the wheels or the print bed as it moves during printing.

- Allow the print bed and extruder to cool before removing the print.

- When removing your print job only use plastic scrapers. Keep your hands are placed behind the scraper at all times.

- Gently try and lift the build surface from the plate. Do not apply too much force.

- If unable to remove the print, please speak to a staff member.

- Ensure the equipment is turned off when you have finished.

- Remember, if you are unsure about anything, check with a member of staff.

LASER CUTTERS

Laser Cutters

- The laser cutter is operated by staff only

- Do not leave your work unattended or leave the space

- Avoid staring into the laser. Always wear protective glasses

- Stay outside the red-lined area when the laser cutter is in use

- Wait one minute after cutting to allow for the fume extraction

- Only use materials provided by staff; No BYO materials.

- If a small fire occurs, press the emergency stop button and call staff immediately

- If the fire persists, use a fire blanket

- If fire danger continues, spray with water or use a fire blanket

HEATING TOOLS

Heating Tools

- After checking the area is clear and the equipment is in good working order, turn on the smoke absorber.

- Do not touch the hot end of the tool you're working with.

- Make sure to use a ceramic tile as the work area must be heat resistant.

- Ensure your work is secured with a clamp to prevent it moving.

- Before using any equipment make sure to tie back loose hair, clothing or jewellery.

- Use pliers or other tools to move and hold hot metal objects.

- Ensure safety glasses are worn.

- Ensure cables are kept away from the tool’s hot end and do not touch molten plastic or solder.

- When you have finished turn the equipment off. Leave the smoke absorber on whilst the equipment cools down for 15 minutes.

- After equipment has cooled down pack everything away safely.

- Remember, if you are unsure of anything, check with a member of staff.

WORKSHOP TOOLS

Workshop Tools

- Check the area is clear and the equipment is in good working order. Report any problems to staff.

- Wear appropriate PPE.

- Ensure the work surface is even.

- Remember, if you are unsure of anything, check with a member of staff.

Blades and cutters

- Before cutting make sure you are using a cutting mat and/or appropriate surface.

- Secure the item to be cut with rulers, jigs or clamps before cutting.

- Check the blade isn’t loose, chipped or dull.

- Always cut away from yourself and keep your hands clear.

Pliers and clamps

- Keep hands clear of tool faces or clamp areas when securing your job.

- Do not apply too much force.

Hammers and mallets

- Ensure there are no people nearby and there is enough clearance before using the hammer or mallet.

- Always use a wooden work surface under the object you are striking.